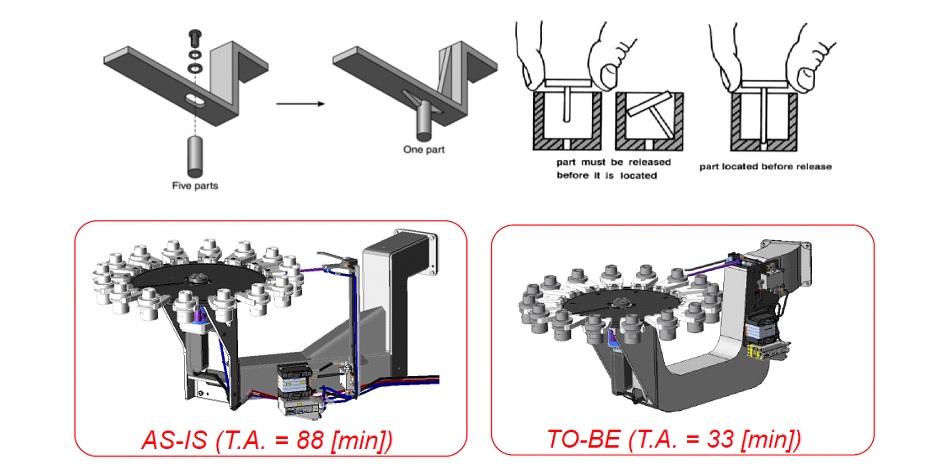

Design for Assembly

Design for Assembly secondo approccio Boothroyd and Dewhurst per la riduzione del numero di componenti e del tempo di assemblaggio.

Conceptual Design for Assembly secondo approccio Stone & McAdams usato nelle fasi concettuali di progettazione per la riduzione dei costi di assembly e dei processi produttivi.

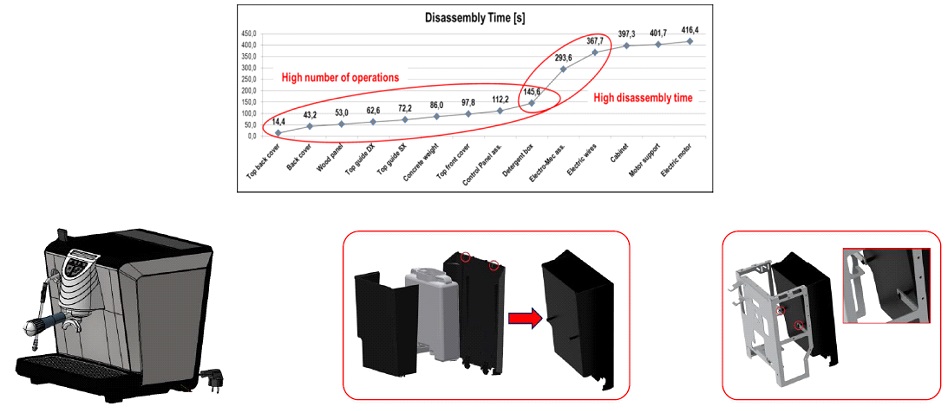

Design for Disassembly

Design for Disassembly secondo approccio della Matrice delle Precedenze e delle Sequenze di Smontaggio, per identificare operazioni critiche e percorsi critici di disassembly

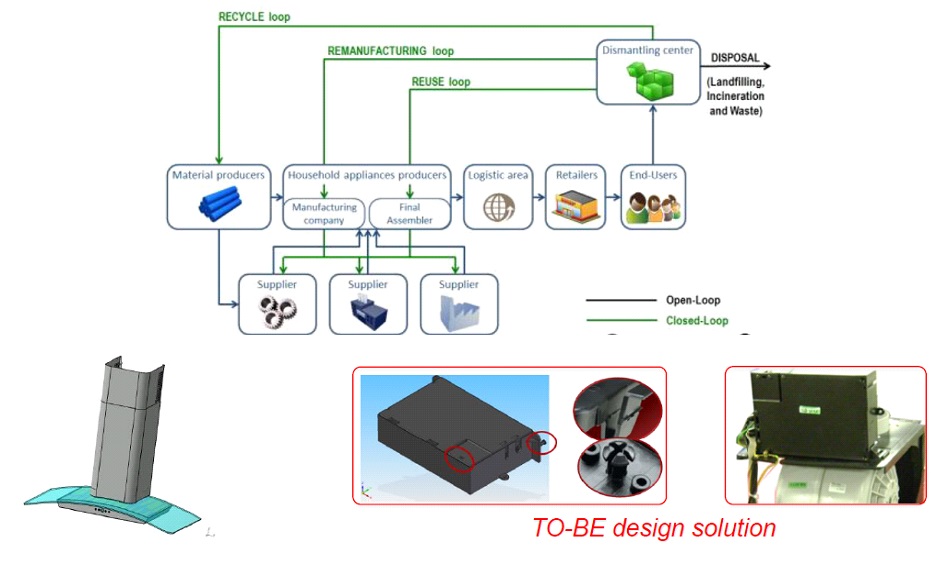

Design for End of Life

Design for End of Life secondo approccio della Materials Selection per il rispetto delle normative (REACH, RoHS, etc.) e per aumentare la riciclabilità di prodotto.

Le attività di ricerca vengono svolte nel laboratorio di Virtual Prototyping.